- Home

-

Vinyl & more..

-

Heat Transfer Vinyl (Textiles)

>

- Vinyl & Letter Remover

- PU-FLEX 20in HTV

- PU-FLEX 13in HTV

- Easyweed 12in

- Easyweed Stretch 15in

- Easyweed Extra - Nylon

- Easyweed Electric 15in

- GLITTER Vinyl 20in

- Patterns HTV

- METALLIC & FOILS Vinyl 20in

- Glow in the Dark HTV

- Reflective HTV

- FLOCK HTV Vinyl

- Brick & PUFF 3D Vinyl

- Dye Sublimation Vinyl

- Printable Vinyl (Eco-Solvent)

- Transfer Application Tape

- T-Shirts & Blanks >

- Vinyl Cutters & Supplies

- Heat Transfer Press >

- Heat Press Accessories

- PSV Permanent Sticker - YARD

- Printable Sticker Vinyl

- Inkjet Transfer - Paper

- Sublimation Paper & Blanks

- Inkjet Printable - Vinyl

- Laser Transfer - Paper >

- Plastisol Transfer - Paper

- Screen Print Foils

-

Heat Transfer Vinyl (Textiles)

>

-

Inks & Supplies

-

Plastisol Inks

>

- Whites & Black

- Additives & Bases

- AP - All Purpose Inks

- HO/LB - Poly Low Bleed Inks

- LC - Low Cure Inks

- 4C - Process Inks

- SPT - SPOT Process Inks

- FL - Fluorescent Inks

- TF - HotSplit Transfer Inks

- GT - Glitter Inks

- MET - Shimmer & Metallics

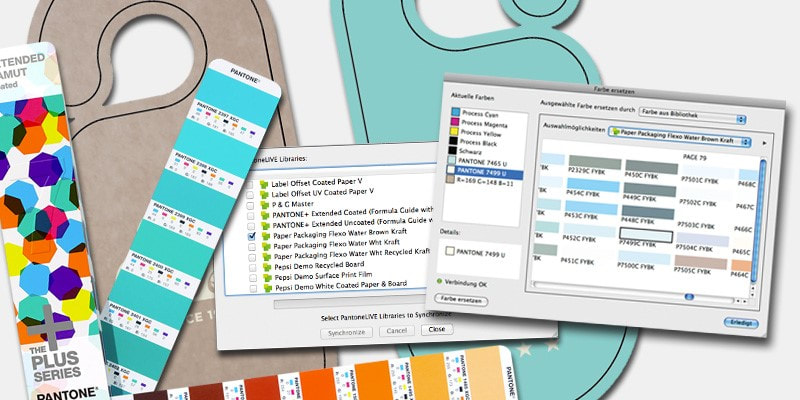

- PMS - Pantone Colors

- PIM - PMS Mixing System

- REF - Reflective Inks

- PHS - Glow in the Dark

- PHC - Photo-Chromatic Inks

- SXF - Special Effects Inks

- Pad Printing Inks

- Latex Inks - Balloons

- Waterbase Inks

- Adhesives

- Spot Removers/ Cleaners

- Chemicals/Reclaim

- Emulsions

- Aluminum Frames

- Mesh for Screens

- Squeegees

- Screen Printing Supplies

- Output Film - Inkjet/Laser

- Color Separation Programs

-

Plastisol Inks

>

-

Equipment

-

DTF & UVDTF

- Gang Sheet Builder for DTF

- How to setup DTF Gang sheet

- Specs for DTF & UVDTF

- DTF Stock Designs

- DTF Printers >

- DTF Ink & Supplies

- UV DTF Printers >

- UV DTF Supplies

- Sublimation Printers >

- Mimaki Wide Format Printers >

- Heated Laminator

- Inkjet Printers

- Laser White Toner Printers >

- Vinyl Plotters/Cutters >

- Financing

- Specials

- Training

- Trade Shows

- Contact us

|

LC - Low Cure Plastisol Inks

Non-Phthalate/PVC Plastisol Inks (LC Inks) The Low Cure Series is WM’s most versatile series on the market, enabling you to print on the most difficult substrates, Polyester 100%. Not only does this system hold up to the worst bleeders, but at the lower cure temps it could save a shop a ton of money in reduced energy costs. CURES at: 230ºF

|

WM Low Cure Poly Inks - excellent for items that require lower curing temperature, such as shopping bags, polyester Dri-fit and Poly Blend fabrics. Inks can be cured at the Flash unit with a min. temp of 230F.

|

LC - Low Cure Fluo Colors

|

Low Cure - Pantone Color Match

- Modifiers: Modifications are not recommended unless completely necessary. To reduce viscosity use Curable Reducer (I10-9906), improve stretch use G&S Base (I10-1020) & puff use Puff Additive (I10-9903). ANY modification will effect Low Cure properties.

- Squeegee Blade: Sharp /Straight Edge, 70-75duro Medium to hard at a 45 degree angle.

- Flashing: 700ºF for 3-5 seconds, **just enough for the surface to be tack free.

- Fusion/Curing: 230º F/121 C for 1 ½ minutes.

- Wash-up: Plastisol Press Wash

- Storage: 70 to 80 F. Due to the ability to cure at low temperatures, this is extremely important. Ink will become thicker over time but can be reduced to a printable viscosity.